|

CNC Series : Sliding Single-column EDM (Ram type) M1310 ~ M1510 |

|

The X. Y& Z axis utilizes AC servo motor.

Multi-cavities machining, ORBIT-CUT machining & Helix machining.

A.T.C. (Automatic Tool change) & C-axis machining available.

The Circle Angle of Sparking is lower than 0.02mm.

The best surface roughness (Ra) is better than 0.1 µm.

Multi-side ORBIT-CUT machining for X, Y & Z axis

High speed and long distance jumping.

Special Rib shape machining function.

|

|

|

|

| X, Y-Travel |

1400 x 700 mm |

1500 x 1000 mm |

| Z-Travel |

500 mm |

600mm |

| Table Dimension |

1850 x 1000 mm |

1580 x 1100 mm |

| Work Tank Dimension |

2010 x 1300 x 500 mm |

2070 x 1620 x 650 mm |

| Max. Table-Quill Distance |

550~1050mm |

750~1350mm |

| Max. Electrode Weight |

100 kgs |

200 kgs |

| Max. Table Loading |

8500 kgs |

11000 kgs |

| Dielectric Tank Capacity |

2000 Litre |

3200 Litre |

| Filters |

6 pcs |

8 pcs |

| Machine Weight |

8100 kgs |

13600 kgs |

| Machine Height |

3370 mm |

3670 mm |

| Ground Area |

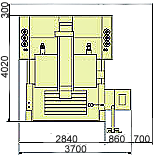

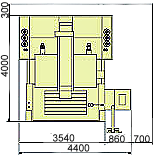

|

|

| Nominal Current |

60A / 5A, 90A / 5A, 120A / 5A |

| Input Voltage |

220 / 380 / 415 / 440V |

| Connected Rating |

7KVA / 10KVA / 13KVA |

| Max. Stock Removal Rate |

400 / 600 / 800mm³/min |

| Best Surface Roughness |

Ra ≦ 0.1μm |

| Best Electrode Wear Rate |

< 0.2% ( with specific equip.< 0.1%) |

Standard accessories |

Additional Equipment |

| Precision Electrode Clamps |

ATC (Auto Tool Change) |

| Piezoelectric Light |

C-Axis |

| Work Fastening Tool Kit |

"EROWA" Chuck-Swiss |

| Magnetic Induction Oil Nozzle Base |

3R System Chuck-Swedish |

| Operation Manuals |

Di-Electric Cooler |

| M.F.D (Fine Mirror Finish) |

Electric Oil |

| X, Y, Z Axis Linear Scales (1μm) |

Permanent Magnetic Chuck |

| |

Automatic Fire Extinguisher |

|

Charge Coupled Device (CCD) |

| ․ Networking monitoring CNC machine (option) |

|